With special thanks to:

De Ridder Precisiemachines, Jos van den Biggelaar, Thomas Knoops, Nebo Special Tooling B.V., Bram van den Berg, Canon Medical Systems Europe B.V. and Jeroen Brinkhuis for all their knowledge and expertise.

Project coordination, video: Annick Vroom

Photography: Erik and Petra Hesmerg

And the Rijksmuseum, Amsterdam, Frits Scholten for the loan

Seeking Direction

The original idea for this series of contemporary prayer notes comes from a simple but urgent point of view: that a single image – despite the noise, abundance and cynicism of our time – can still give us direction.

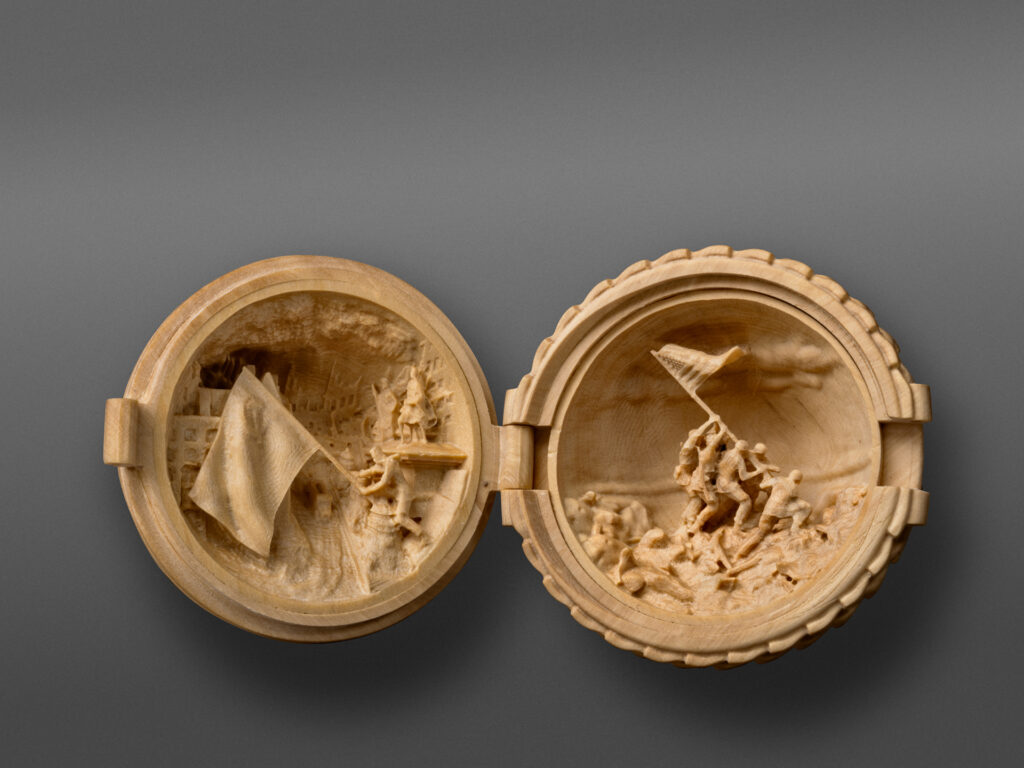

Scattered around the world in museums and private art collections, one can come across fascinating prayer notes, body jewelry made in the early sixteenth century: as small as golf balls, carved from boxwood. When one opens them, they reveal meticulously carved scenes from the life and sufferings of Christ: sculptural, almost cinematic and steeped in symbolism. Images in their most concentrated form: small, precise and meaningful.

Inspired by these small historical objects, and created in close collaboration between historical research, medical scans, digital production and 5-axis “high-speed micro-milling” technology, Carved Time was created: a series of contemporary prayer notes, body jewelry carved from boxwood.

A prayer note through the CT scan

The first step in this project was to put an original prayer note from the collection of the Rijksmuseum, Amsterdam (object number BK-1981-1, workshop Adam Dircksz, Delft) through a CT scanner to obtain the highest possible data. This digital scan was then edited to preserve the original Gothic meshwork. The only thing that was modified on the exterior was the text. This was replaced with sections from the first article of the or the Universal Declaration of Human Rights, “born free and equal in dignity and rights” and “in a spirit of brotherhood.” The interior was completely redesigned.

Turning Points in Our Recent History

These new prayer notes do not show religious scenes. They depict micro-sculptures of key moments in recent history. Here the focus is not on the divine that is central, but on the human dimension, vulnerability and conscience.

Carved Time reminds us of sixteen turning points in our recent history. Iconic images that have forever etched themselves in our memory, such as the Tank Man, the Napalm girl, Abu Ghraib, the Falling Man or the murder of George Floyd. Or the iconic images at the end of World War II: Russian soldiers raising a flag on the Reichstag in Berlin, and American soldiers planting a flag on Iwo Jima. Moments when the world stopped for a moment and had to be revisited.

Carved Time recaptures the ancient form of the sixteenth-century prayer note, once an instrument of Christian devotion, and places it at the heart of our contemporary visual culture. An invitation to pause and reflect, to look closely and reflect; to serve as a contemporary moral compass.